European standard customized sigma roll forming machines manuafaturer with ISO quality system| ZHONGYUAN

- group name

- Metal Sheet Roll Forming Machines

- Min Order

- 1 piece

- brand name

- ZHONGYUAN

- update time

- Tue, 21 Apr 2020 18:58:18 GMT

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

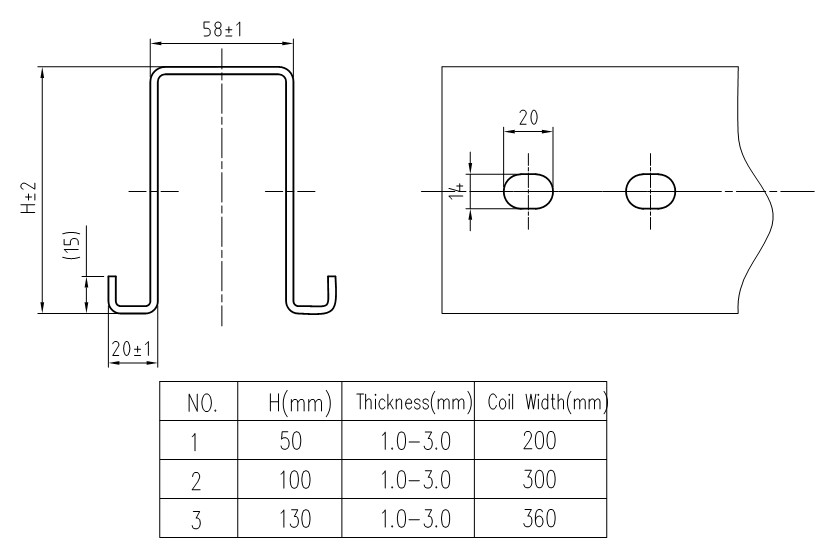

Sigma Forming Machine

| Technical data of Sigma forming machine | |

|---|---|

| Suitable Material | Cold-rolled steel strip and heat-treated galvanized steel strip |

| Thickness of raw material | 1.0-3.0mm (235-345Mpa) |

| Size of OMEGA | 50-130mm adjustable (special size available) |

| Material of roller | Cr12 mould steel being quenched treatment,HRC58-60 |

| Material of cutter blade& punching die | Cr12 mould steel with quenched treatment, HRC58-60 |

| Material of shaft | High quality 45# steel with heat treatment. Roller grinder milling. |

| Forming speed | about 10-12m/min |

| Power Requiremen | Main motor power: 15 Kw(Depend on final design) |

| Hydraulic station power: 5.5Kw (Depend on final design) | |

| Diameter of shaft for rollers | 82mm |

| Controlling system | Mitsubishi PLC & converter |

| Quantity of rollers | about 22stations for main rollers |

| Weight of machine | About 10000KGS |

| Size of machine installation | About 20mX2.5mx1.7m |

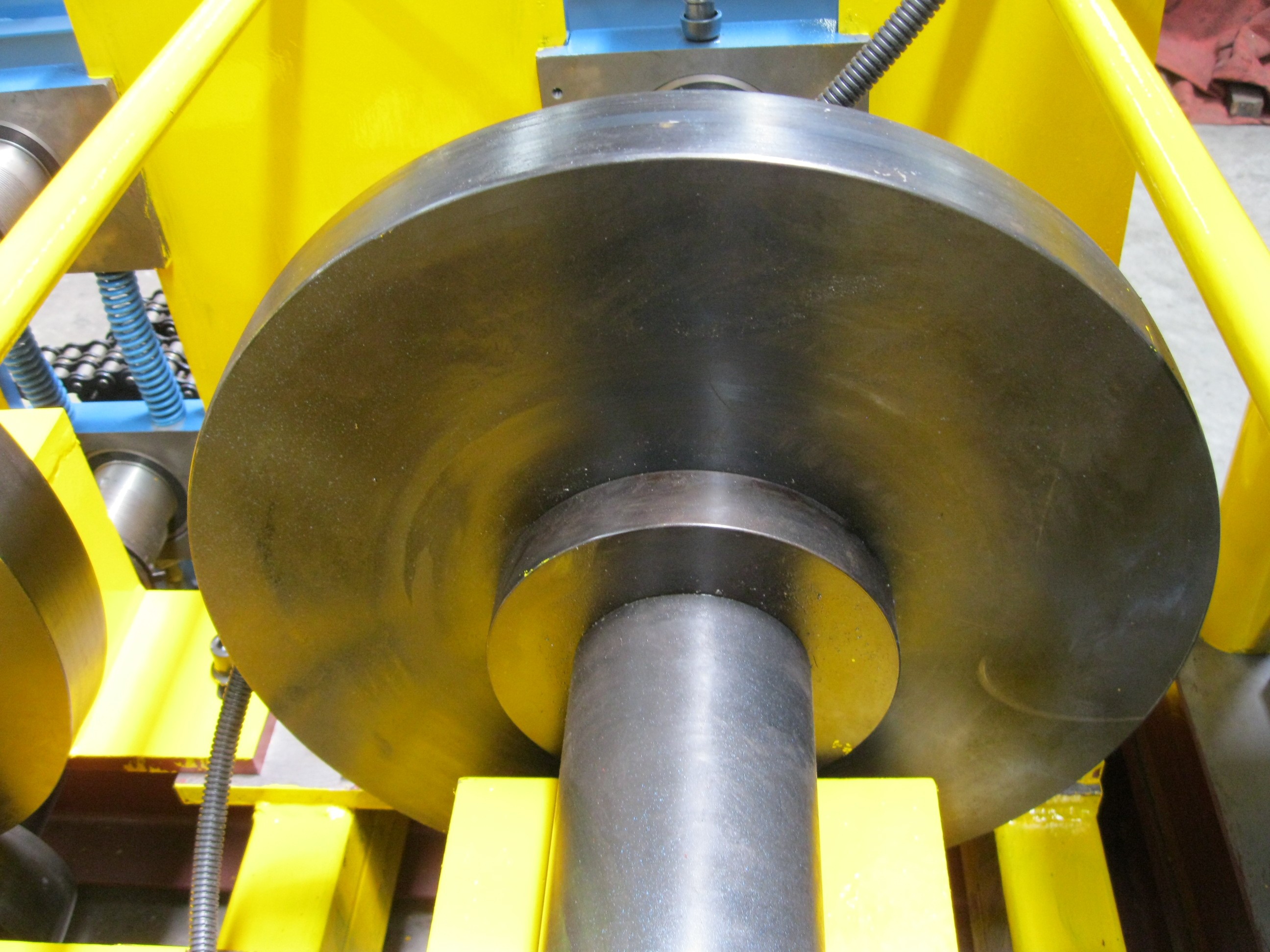

Anti-rust roller:

Cr12 mould steel being quenched treatment,HRC58-60,

CNC machine tooled to increase rollers precision.

Product of Sigma forming machine

Product sample from machine

Our Roll Forming Machine’s advantages

1.Anti-rust roller: Cr12 mould steel being quenched treatment,HRC58-60,

CNC machine tooled to increase rollers precision.

2. Heat treatment: Heat treatment for cutting frame to remove the steel stress, to avoid deformation.

3. Cutter blade: Cr12 mould steel with quenched treatment, long life time.

4. High precision: shafts for rollers are tooled by grinding machine at least twice. Rollers are CNC processed to ensure precision performance.

5. People originate: introduced Mitsubishi PLC with touch screen. Friendly man-machine interaction.

6. Excellent services: Technician can be sent to your factory to install the machine and train your workers. Lifetime services for our machines.